Find unused space and fill it to full capacity by increasing hanging density

- Identify reasons for gaps and use a hanging system that eliminates gaps.

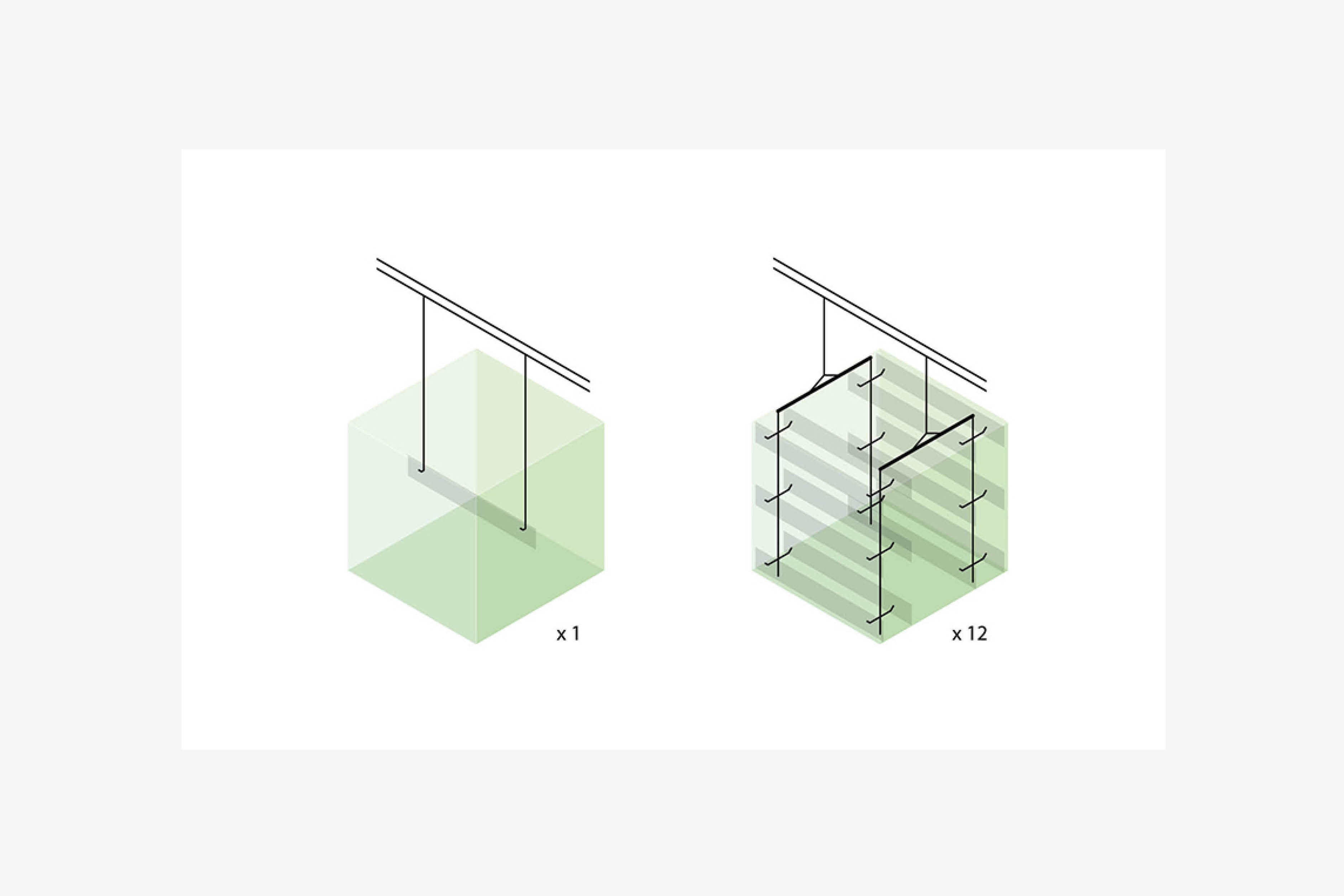

- Use full height, for instance by pre-hanging small parts on hangers that utilize full coating height, such as HQS.

- Use depth. Slim and airy parts hung at full depth can increase capacity, by using for instance HCS, H11B.

Handle hanging marks

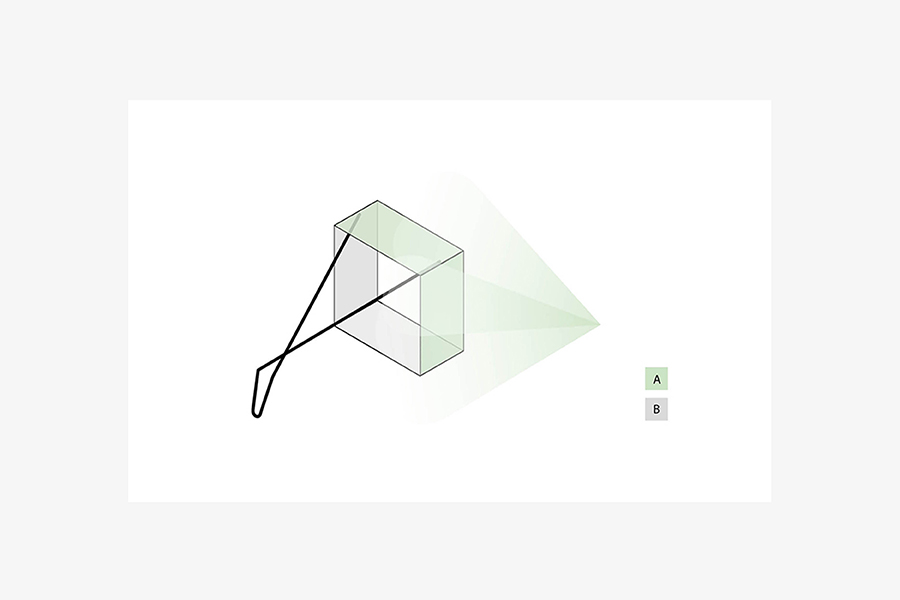

- Remember that many parts have an A and a B side, a natural back or surfaces that do not have to be coated 100%. Use hanging methods that save coating and minimize hanging marks, such as BHL Y, ROB.

- Use hanging products that leave minimal hanging marks. Hang on as thin material as possible, for instance sheet arrows with sharp edges or thin spring wires, such as HQL.

Make sure hanging is stable and offers good contact

- Use tension hanging – for instance with spring wire insert, BHL Y.

- Find more than one contact surface, for instance by hanging on two or more hooks or by using arrows or metal sheets that in one go offer several contact points and thus stabilize hanging.

- Remember that good contact is generally created by hanging on sharp edges, such as arrows and HQS.

Handle problems with curves

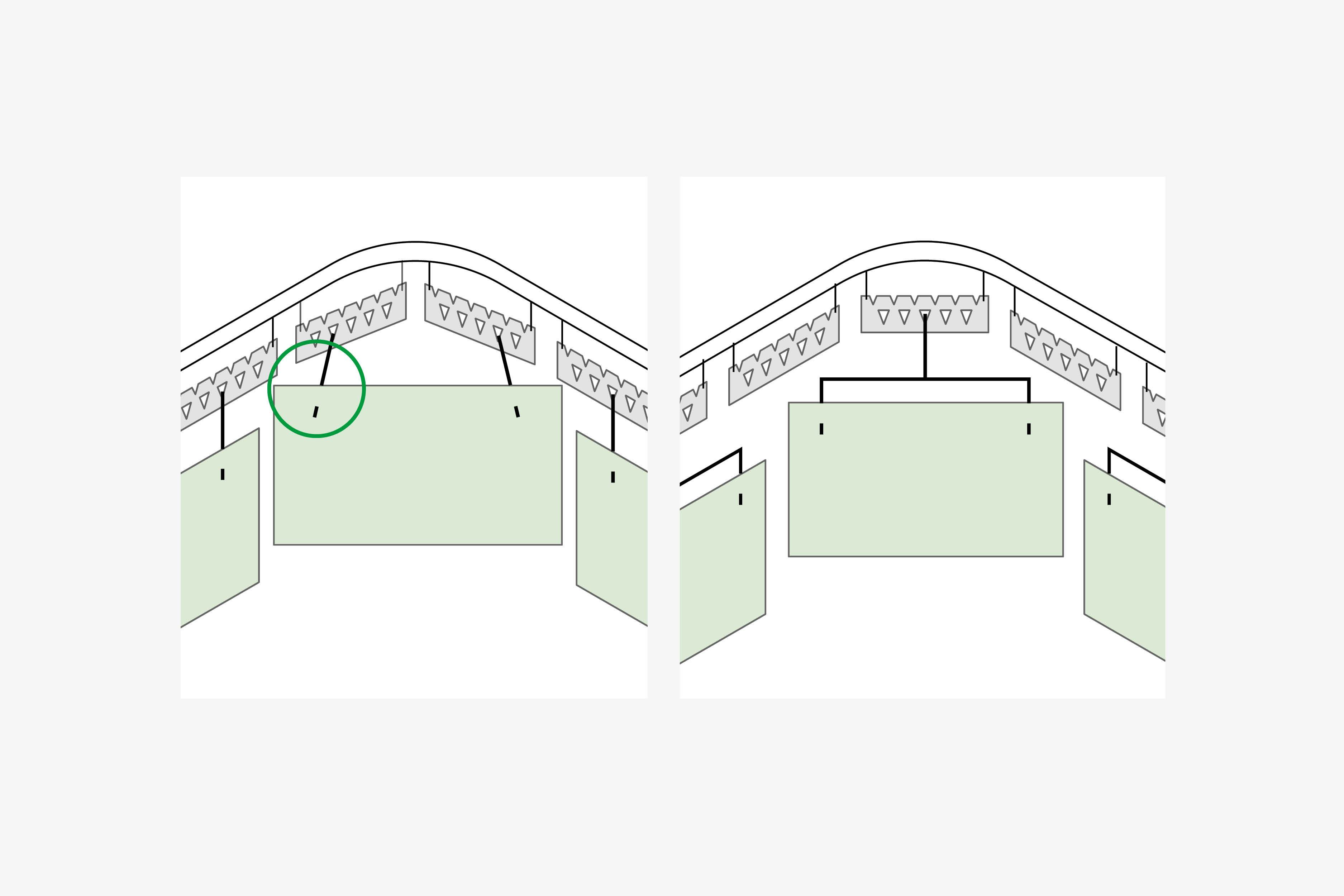

- Avoid tension from strained hooks by having a suspended beam between the conveyor and item – or use swivels or rotational devices, for instance ROT 03.

Handle problems with slopes

- Avoid problems with slopes by one point hanging, for instance shafted suspension beams or frames, H11B, HCF.

Handle density

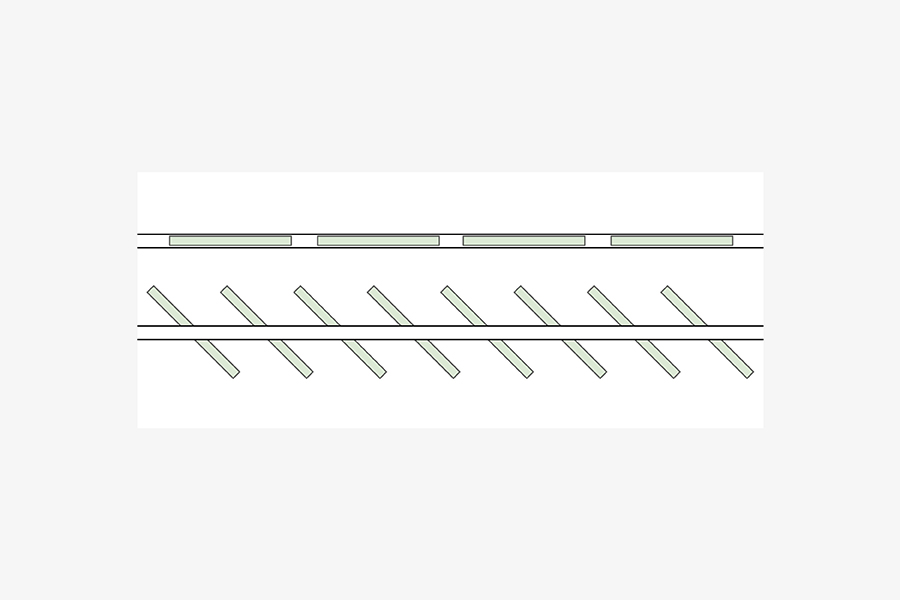

- One way of solving the problem and also getting higher density in the coating line is to use 45° angled hooks or suspension beams on 45° angled shafts (figure shows line from above)